info@gerb.com

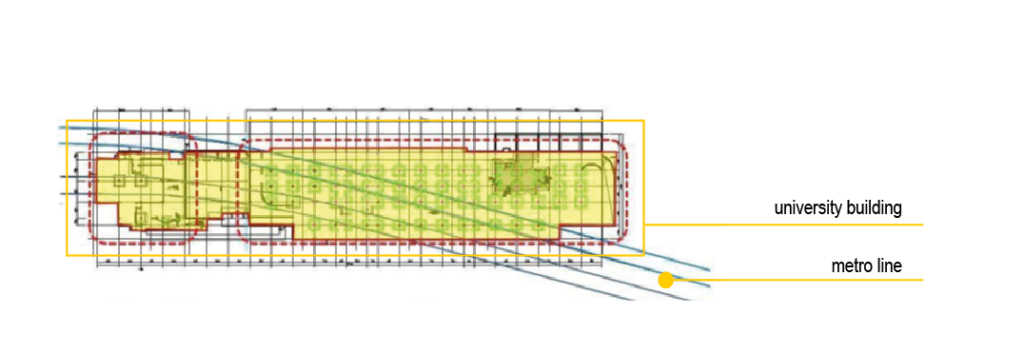

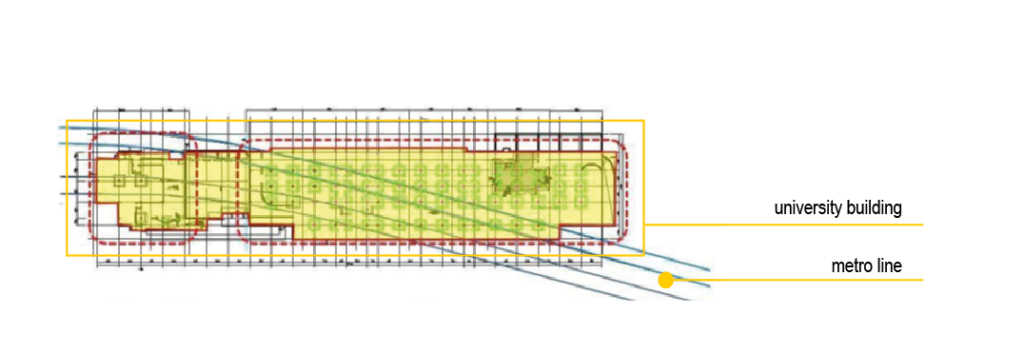

Vibration Isolation of Beijing University landscape building

Protecting teaching experimental equipment from vibration and structure-borne noise

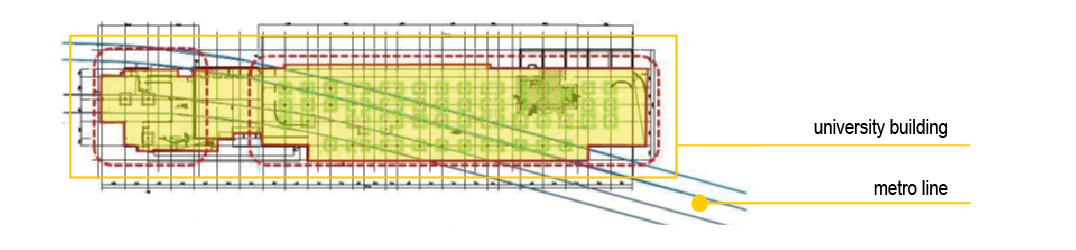

The extension of Beijing University was completed at the end of August 2021 with a new teaching and office building providing more space for students and staff. GERB has already supported the project in 2018 with engineering and delivering an elastic support solution to protect members and structures from unwanted vibrations.

Challenge

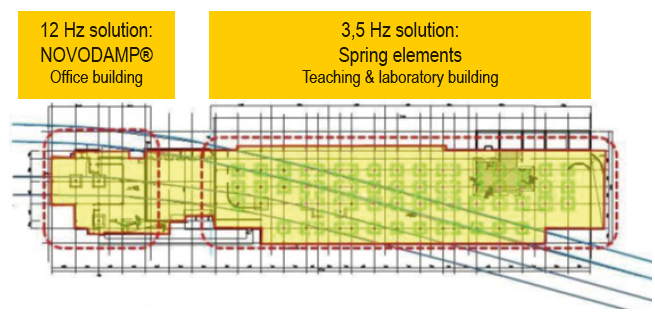

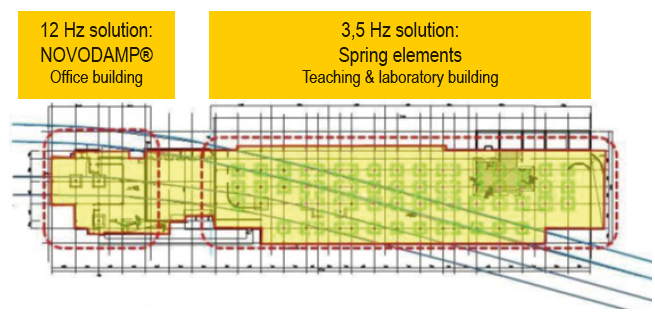

A subway line running underground threatened the new structure with negative effects of vibration that could cause affect the normal use of the teaching equipment as well as a significant reduction of comfort for people in the building. Inspired by several reference projects, such as Shanghai Symphony Orchestra building with similar requirements, GERB proved to be a good partner for this project. In close contact with the local consultants and structural engineers, GERB developed a customized solution.

Technical Facts:

Structure: reinforced concrete

Design load: 330,000 kN

Vibration source: underground metro

Support frequency: 3.5 Hz

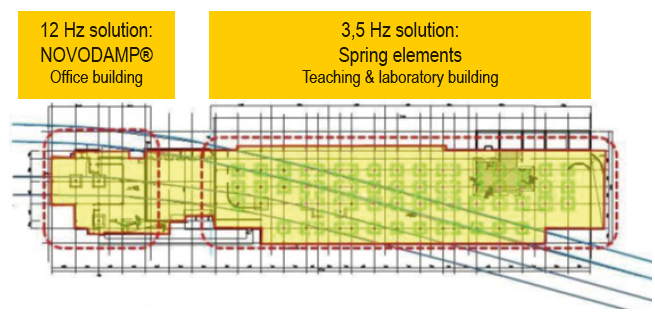

Solution

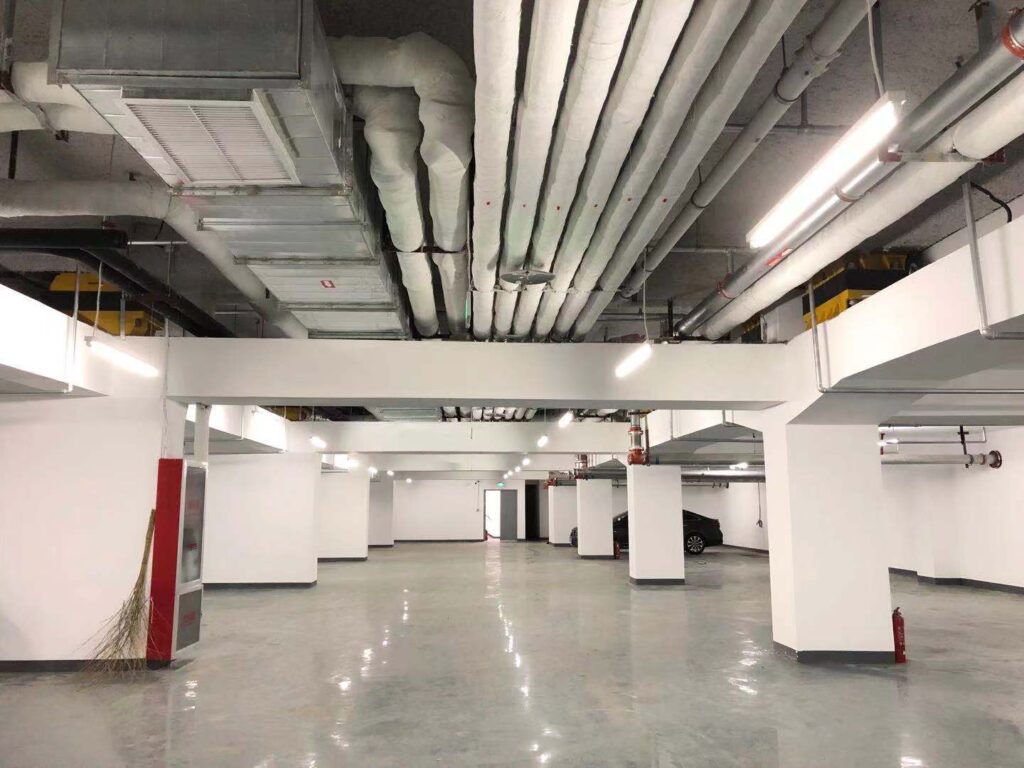

With the implementation of 220 prestressable GP spring elements containing helical steel and a supplement design of our closed-cell polyurethane NOVODAMP®, we were able to reduce negative effects of vibration and structure-borne noise. By also providing engineering service, installation instructions and measurement our client could benefit from our full-range supply.

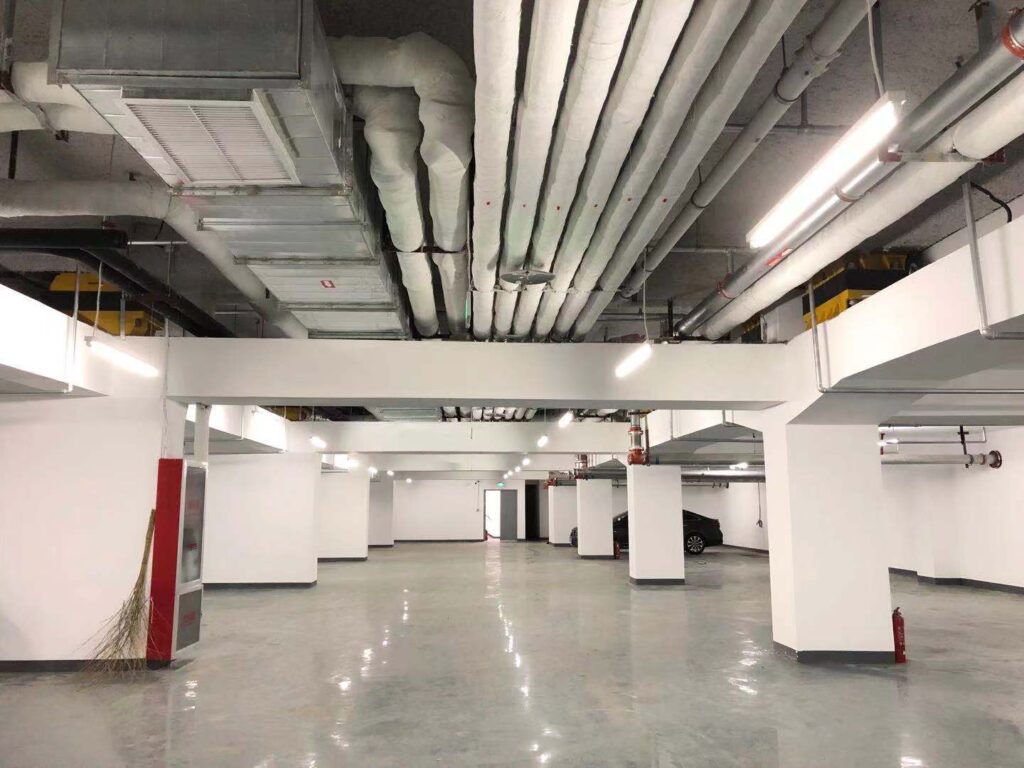

Implementation

Further Resources

You need further information on this topic?

Please do not hesitate to contact us with your individual question.

One of our project engineers will get back to you shortly.

Vibration Isolation of Beijing University landscape building

Protecting teaching experimental equipment from vibration and structure-borne noise

The extension of Beijing University was completed at the end of August 2021 with a new teaching and office building providing more space for students and staff. GERB has already supported the project in 2018 with engineering and delivering an elastic support solution to protect members and structures from unwanted vibrations.

Vibration Isolation of Beijing University landscape building

Protecting teaching experimental equipment from vibration and structure-borne noise

The extension of Beijing University was completed at the end of August 2021 with a new teaching and office building providing more space for students and staff. GERB has already supported the project in 2018 with engineering and delivering an elastic support solution to protect members and structures from unwanted vibrations.

Challenge

A subway line running underground threatened the new structure with negative effects of vibration that could cause affect the normal use of the teaching equipment as well as a significant reduction of comfort for people in the building. Inspired by several reference projects, such as Shanghai Symphony Orchestra building with similar requirements, GERB proved to be a good partner for this project. In close contact with the local consultants and structural engineers, GERB developed a customized solution.

Technical Facts:

Structure: reinforced concrete

Design load: 330,000 kN

Vibration source: underground metro

Support frequency: 3.5 Hz

Challenge

A subway line running underground threatened the new structure with negative effects of vibration that could cause affect the normal use of the teaching equipment as well as a significant reduction of comfort for people in the building. Inspired by several reference projects, such as Shanghai Symphony Orchestra building with similar requirements, GERB proved to be a good partner for this project. In close contact with the local consultants and structural engineers, GERB developed a customized solution.

Further Technical Facts:

Structure: reinforced concrete

Design load: 330,000 kN

Vibration source: underground metro

Support frequency: 3.5 Hz

Solution

With the implementation of 220 prestressable GP spring elements containing helical steel and a supplement design of our closed-cell Polyurethane NOVODAMP®, we were able to reduce negative effects of vibration and structure-borne noise. By also providing engineering service, installation instructions and measurement our client could benefit from our full-range supply.

Solution

With the implementation of 220 prestressable GP spring elements containing helical steel and a supplement design of our closed-cell Polyurethane NOVODAMP®, we were able to reduce negative effects of vibration and structure-borne noise. By also providing engineering service, installation instructions and measurement our client could benefit from our full-range supply.

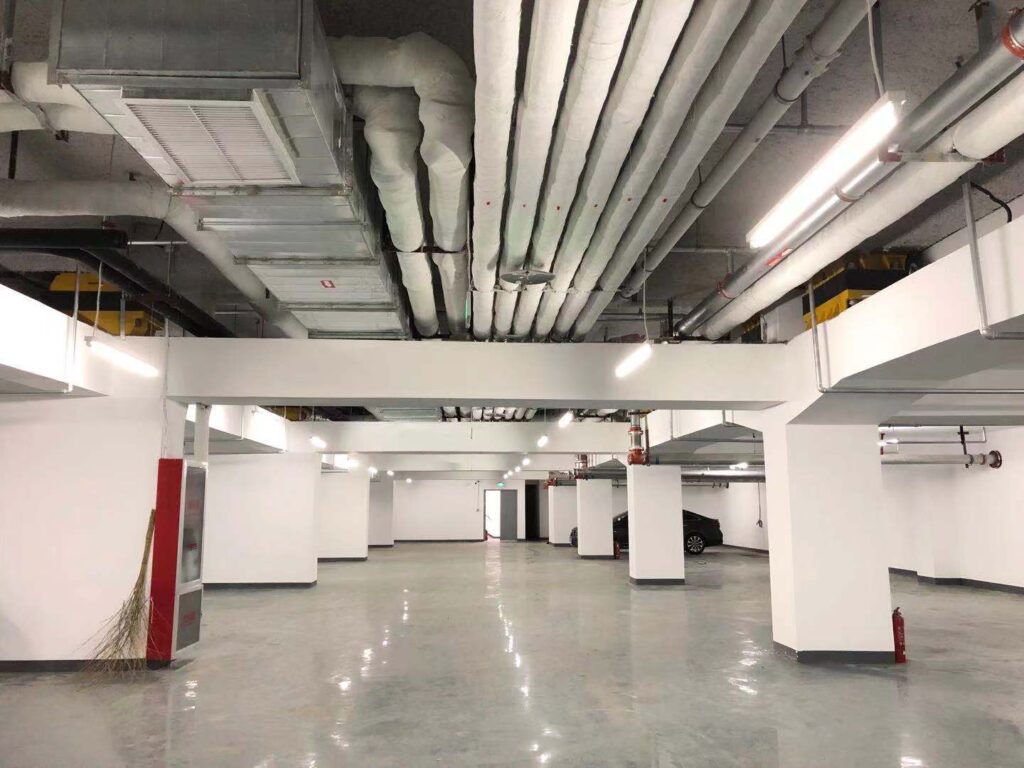

Implementation

Implementation

Share this post

Further Resources

You need further information on this topic?

Please do not hesitate to contact us with your individual question.

One of our project engineers will get back to you shortly.

Further Resources

You need further information on this topic?

Please do not hesitate to contact us with your individual question.

One of our project engineers will get back to you shortly.